Mazda 2: Transaxle Fluid Temperature (TFT) Sensor

TRANSAXLE FLUID TEMPERATURE (TFT) SENSOR INSPECTION

CAUTION:

- Water or foreign objects entering the connector can cause a poor connection or corrosion. Be sure not to drop water or foreign objects on the connector when disconnecting it.

On-Vehicle Inspection

1. Disconnect the coupler component connector.

- Disconnect the negative battery cable.

- Disconnect the coupler component connector.

2. Measure the resistance between the coupler component terminals E and H.

- If there is any malfunction, replace the TFT sensor. (See TRANSAXLE FLUID TEMPERATURE (TFT) SENSOR REMOVAL/INSTALLATION).

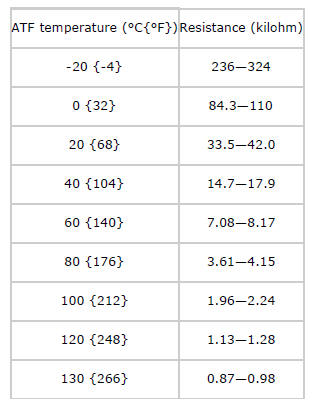

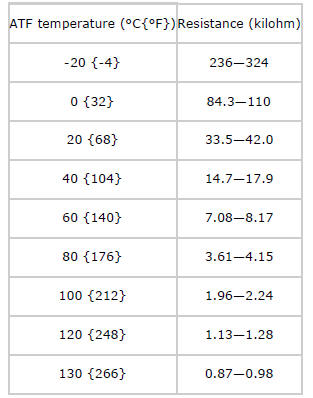

TFT sensor specification

Off-Vehicle Inspection

1. Place the TFT sensor and a thermometer in ATF as shown, and heat the ATF gradually.

WARNING:

- A hot ATF and beaker can cause severe burns. Do not touch them.

2. Measure the resistance between the coupler component terminals E and H.

- If there is any malfunction, replace the TFT sensor.

TFT sensor specification

TRANSAXLE FLUID TEMPERATURE (TFT) SENSOR REMOVAL/INSTALLATION

WARNING:

- A hot transaxle and ATF can cause severe burns. Turn off the engine and wait until they are cool.

- Using compressed air can cause dirt and other particles to fly out, causing injury to the eyes. Wear protective eyeglasses whenever using compressed air.

CAUTION:

- Water or foreign objects entering the connector can cause a poor connection or corrosion. Be sure not to drop water or foreign objects on the connector when disconnecting it.

1. Remove the control valve body.

- Disconnect the negative battery cable.

- Clean the transaxle exterior throughout with a steam cleaner or cleaning solvents.

- Drain the ATF into a separate suitable container. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT).

- Remove the oil pan.

- Remove the control valve body. (See CONTROL VALVE BODY REMOVAL/INSTALLATION).

- Disconnect the coupler component connector.

- Remove the coupler component from transaxle case.

- Remove the O-ring from the coupler component.

2. Install the control valve body.

- Apply ATF to a new O-ring and install it on the coupler component.

- Install the coupler component to transaxle case.

- Connect the coupler component connector.

- Install the control valve body. (See CONTROL VALVE BODY REMOVAL/INSTALLATION).

CAUTION:

- If any sealant remains on the sealing surfaces of the transaxle case and oil pan, transaxle damage may occur. Use a cleaning fluid to remove any old sealant from the transaxle case and oil pan.

3. Apply a light coat of sealant (TB1217E or equivalent) to the contact surfaces of the oil pan and transaxle case.

4. Install the oil pan before the applied sealant starts to harden.

CAUTION:

- The removed bolts with spring washer cannot be reused. If they are reused, it could loosen the bolts due to spring weakness.

Tightening torque

- Flange bolt: 6.0-8.0 N*m {62-81 kgf*cm, 54-70 in*lbf}

- Bolt with spring washer: 8-10 N*m {82-101 kgf*cm, 71-88 in*lbf}

5. Add the ATF. (See AUTOMATIC TRANSAXLE FLUID (ATF) REPLACEMENT).

6. Connect the negative battery cable.

7. Perform the "Mechanical System Test". (See MECHANICAL SYSTEM TEST).